Welcome to our websites!

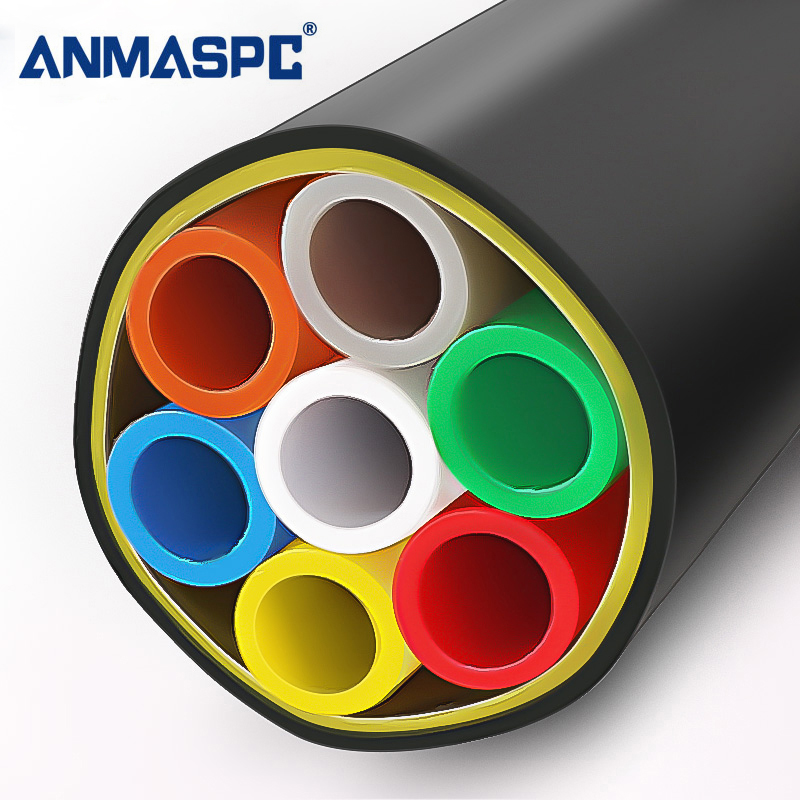

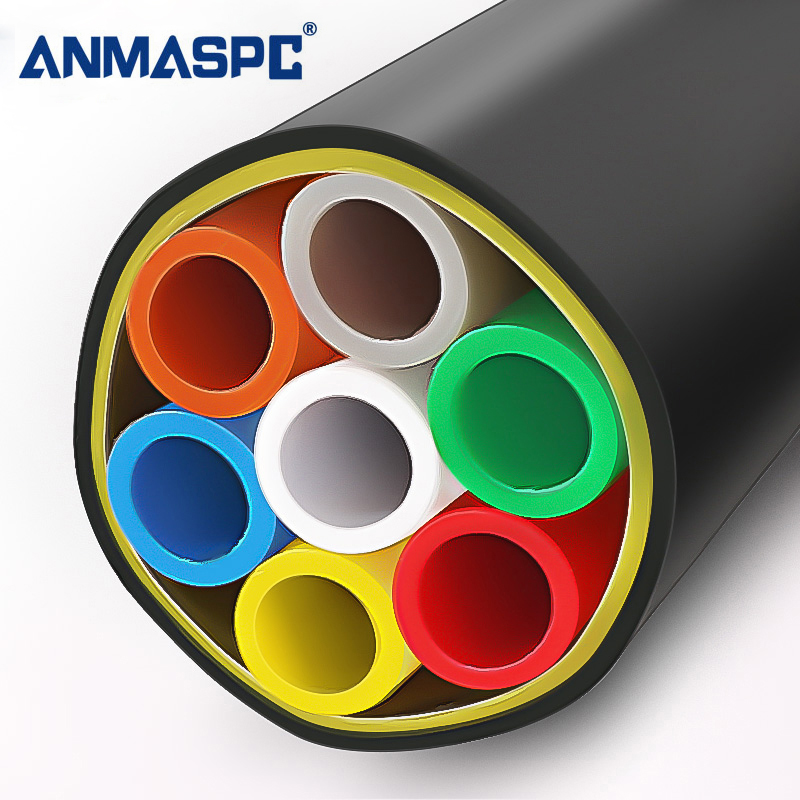

7 Ways 12/10 mm DB HDPE Tube

7 WAYS

A bundle of micro- or mini-tubes (regular wall size) is surrounded by dual HDPE sheath. The design makes the duct assemblies suitable for outdoor direct bury application. The inner micro ducts are optimized for best cable blowing performance.

Raw materials

HDPE of a high-molecular type with the following parameters is used for production of the Tube Bundle: - Melt flow index: 0.1 ~ 0.4 g/10 minutes EN ISO 1133 - Density: Min. 0.940 g/cm3 ISO 1183 - Tensile strength at yield: Min. 20MPa ISO 527 - Elongation at the break: Min 350% ISO 527 - Environmental stress crack resist (F50) Min. 96 hours ISO 4599

|

Pos.

|

Mechanical performance

|

Test conditions

|

Performance

|

Standard

|

|

1

|

Tensile strength

at yield |

Rate of extension:

100mm/min |

≥620N

|

IEC 60794-1-2

Method E1 |

|

2

|

Crush

|

Sample length: 250mm

Load: 380N Duration of Max. load: 1 minutes Recovery time: 1 hour |

The outer and inner diameter shall show, under visual examination without damage and no reduction of diameter greater than 15%.

|

IEC 60794-1-2

Method E3 |

|

3

|

Kink

|

≤120mm

|

-

|

IEC 60794-1-2

Method E10 |

|

4

|

Impact

|

Striking surface radius: 10mm

Impact Energy: 1J Number of impact: 3 times Recovery time: 1 hour |

Under visual examination, there shall be no damage to the micro duct.

|

IEC 60794-1-2

Method E4 |

|

5

|

Bend radius

|

Number of turns: 5

Mandrel diameter:144mm. Mumber of cycles: 3 |

The outer and inner diameter shall show, under visual examination without damage and no reduction of diameter greater than 15%.

|

IEC 60794-1-2

Method E11 |

|

Pos.

|

Item

|

Specification

|

|

|

1

|

Appearance

|

Smooth outer wall (UV-stabilized) without visible impurities; well-proportioned color, no bubbles or cracks; with defined markings

on outer wall. |

|

|

2

|

Tensile strength

|

Use Pull socks to tension a sample in accordance with table below:

Sample length: 1m Tensile speed: 20mm/min Load: 6800N Duration of the tension: 5 min. |

No visual damage or residual deformation greater than 15% of the duct assembly outer diameter.

|

|

3

|

Crush Resistance

|

A 250mm sample after 1 minute load time and 1 hour recovery time. Load (plate) shall be 2000N. The imprint of the plate on the

sheath is not considered as mechanical damage. |

No visual damage or residual deformation greater than 15% of the duct assembly outer diameter.

|

|

4

|

Impact

|

Striking surface radius shall be 10mm and impact energy 10J. Recovery time shall be one out. The imprint of the striking surface

on the microduct is not considered as mechanical damage. |

No visual damage or residual deformation greater than 15% of the duct assembly outer diameter.

|

|

5

|

Bend

|

Diameter of mandrel shall be 40X OD of sample, 4 turns, 3 cycles.

|

No visual damage or residual deformation greater than 15% of the duct assembly outer diameter.

|

Completed packages of the HDPE Tube Bundle on drums can be stored outdoor max. 6 months upon the date of production. Storage temperature: -40°C ~ +70°C Installation temperature: -30°C ~ +50°C Operating temperature: -40°C ~ +70°C

Essential details

- Model Number:7 Ways 12/10mm DB Tube Bundle

- Type:Tube bundle

- Place of Origin:Shanghai, China

- Brand Name:ANMASPC

- Use:FTTH

- Warranty Time:12months

- Network:None

- Sub duct Inner diameter:10mm

- Sub duct outer diameter:12mm

- PE Sheath:3.4mm

- Outer Diameter::42.8mm (±1.1mm)

- Melt flow index:0.1 ~ 0.4 g/10 minutes

- Density:Min. 0.940 g/cm3

- Tensile strength at yield:Min. 20MPa

- Elongation at the break:Min 350%

- Environmental stress crack resist (F50):Min. 96 hours

- Storage temperature:-40°C ~ +70°C

Supply Ability:1000000 Piece/Pieces per Day

Write your message here and send it to us