Welcome to our websites!

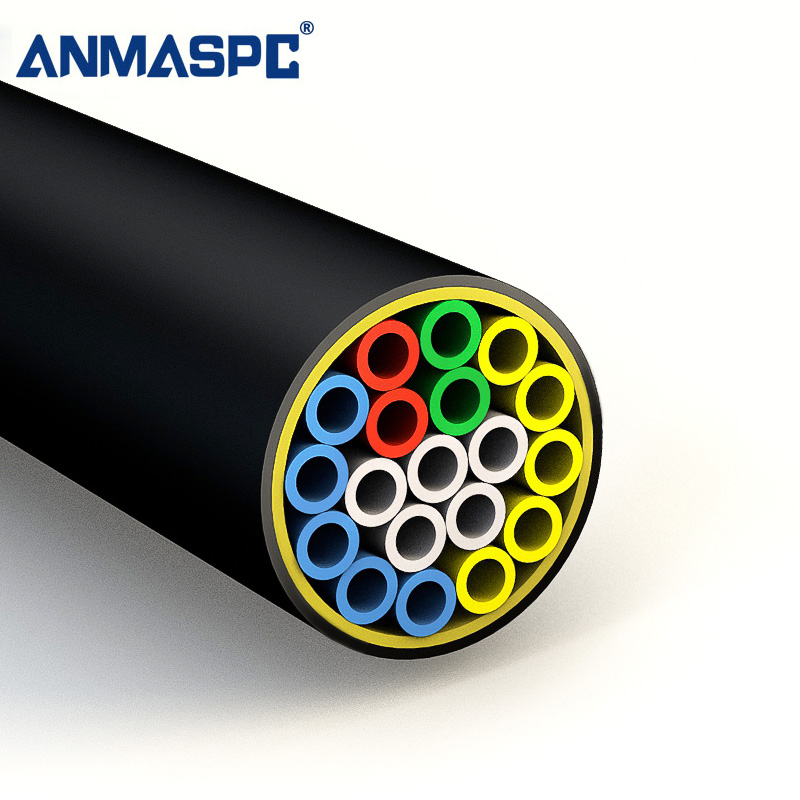

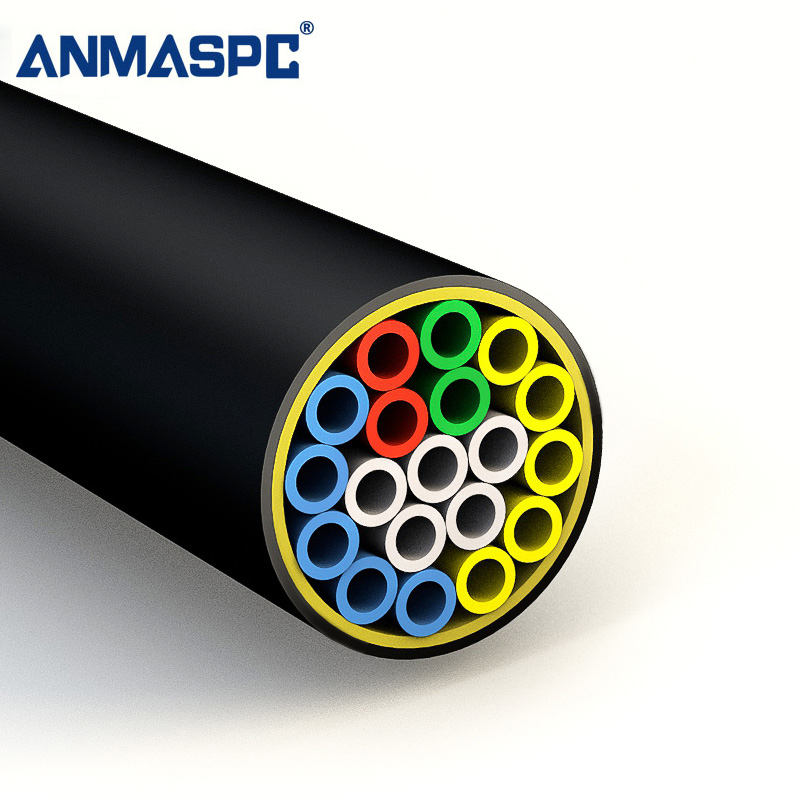

HDPE Pipe 19ways 7/3.5mm PE1.2mm

19 WAYS

|

Physical and Mechanical Properties – Inner Micro duct 7/3.5mm

|

|||

|

1

|

Visual appearance

|

Visual inspection

|

Ribbed inside & smooth outside surface, free from blisters, shrink hole, flaking, scratches & roughness.

|

|

2

|

Outer diameter

|

ANMASPC |

7.0mm ± 0.1mm

|

|

3

|

Wall thickness

|

ANMASPC |

1.50mm ± 0.10mm

|

|

4

|

Inner diameter clearance

|

Blowing steel ball

|

A 3.0mm steel ball can be blown freely through the duct.

|

|

5

|

Ovality

|

ANMASPC |

≤ 5%

|

|

6

|

Pressurization

|

5 minutes @16bar each duct

|

No damage and leakage

|

|

7

|

Kink

|

IEC 60794-1-2 Method E10

|

≤ 70mm

|

|

8

|

Tensile strength

|

Rate of extension:

100mm/min |

≥ 470N

|

|

9

|

Crush

|

Sample length: 250mm

Load: 1650N Duration of Max. load: 1 min Recovery time: 1 hour |

No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test.

|

|

10

|

Impact

|

IEC 60794-1-2 Method E4

1.0 J Impact, recovery time 1 hour |

No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test.

|

|

11

|

Heat reversion

|

110℃ ~ 23℃, 1 hour

|

≤ 3%

|

|

12

|

Min. bend radius

|

84mm

|

No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test.

|

|

13

|

Co-efficient of Friction

|

750mm Diameter, 450°loop, 5kg mass

|

≤ 0.1

|

|

14

|

Color and printing

|

Visual inspection

|

As per customer specification

|

|

Pos.

|

Item

|

Specification

|

|

|

1

|

Appearance

|

Smooth outer wall (UV-stabilized) without visible impurities; well-proportioned color, no bubbles or cracks; with defined markings

on outer wall. |

|

|

2

|

Tensile strength

|

Use Pull socks to tension a sample in accordance with table below:

Sample length: 1m Tensile speed: 20mm/min Load: 9000N Duration of the tension: 5 min. |

No visual damage or residual deformation greater than 15% of the duct assembly outer diameter.

|

|

3

|

Crush Resistance

|

A 250mm sample after 1 minute load time and 1 hour recovery time. Load (plate) shall be 2500N. The imprint of the plate on the

sheath is not considered as mechanical damage. |

No visual damage or residual deformation greater than 15% of the duct assembly outer diameter.

|

|

4

|

Impact

|

Striking surface radius shall be 10mm and impact energy 10J. Recovery time shall be one out. The imprint of the striking surface

on the microduct is not considered as mechanical damage. |

No visual damage or residual deformation greater than 15% of the duct assembly outer diameter.

|

|

5

|

Bend

|

Diameter of mandrel shall be 40X OD of sample, 4 turns, 3 cycles.

|

No visual damage or residual deformation greater than 15% of the duct assembly outer diameter.

|

Completed packages of the HDPE Tube Bundle on drums can be stored outdoor max. 6 months upon the date of production. Storage temperature: -40°C ~ +70°C Installation temperature: -30°C ~ +50°C Operating temperature: -40°C ~ +70°C

Essential details

- Model Number:19ways 7/3.5mm DB Tube Bundle

- Type:Micro Duct & Tube Bundle

- Place of Origin:Wenzhou, China

- Brand Name:ANMASPC

- Use:FTTH

- Warranty Time:12months

- Network:None

- Sub duct Inner diameter:3.5mm

- Sub duct outer diameter:7mm

- PE Sheath:1.2mm

- Outer Diameter::44.4mm (±1.2mm)

- Melt flow index:0.1 ~ 0.4 g/10 minutes

- Density:Min. 0.940 g/cm3

- Tensile strength at yield:Min. 20MPa

- Elongation at the break:Min 350%

- Environmental stress crack resist (F50):Min. 96 hours

- Kink:≤140mm

Supply Ability:1000000 Meter/Meters per Week

Write your message here and send it to us