Welcome to our websites!

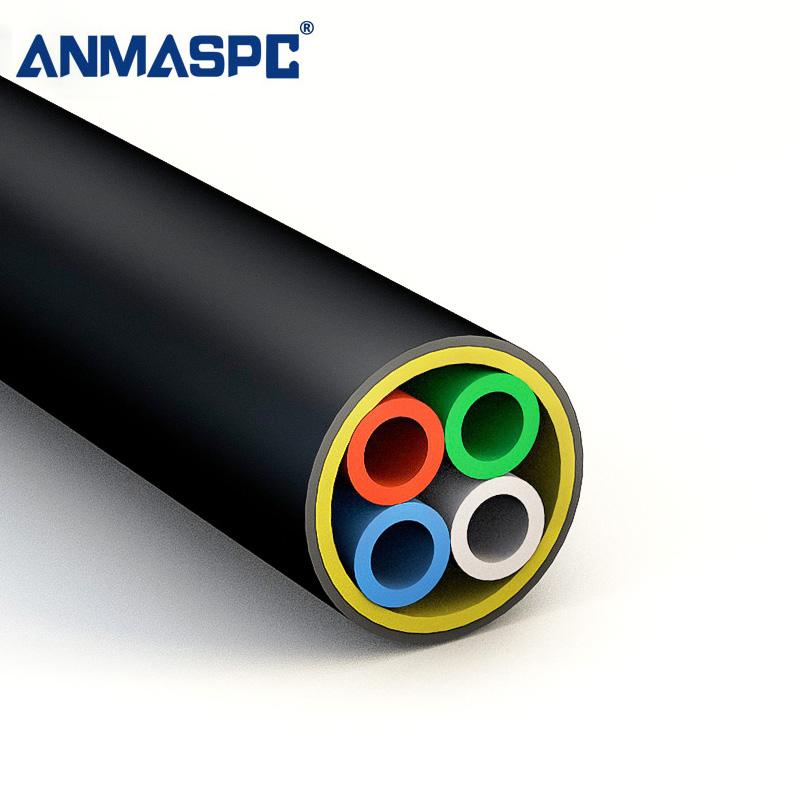

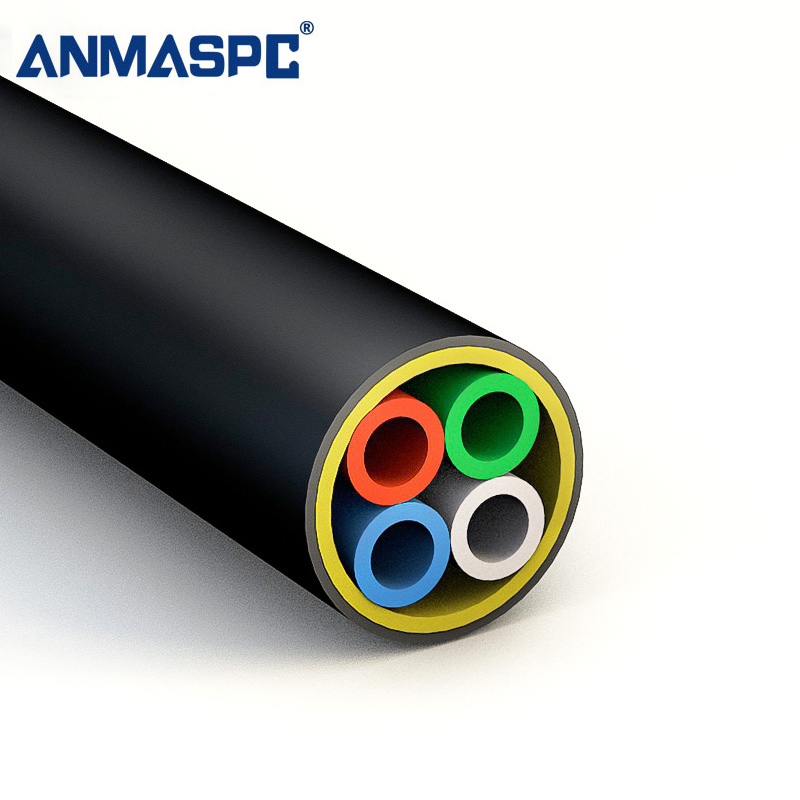

HDPE TUBE 4 ways 12/10mm

4 ways hdpe

|

Physical and Mechanical Properties – Inner Micro duct 12/10mm

|

|||

|

1

|

Visual appearance

|

Visual inspection

|

Ribbed inside & smooth outside surface, free from blisters, shrink hole, flaking, scratches & roughness.

|

|

2

|

Outer diameter

|

ANMASPC |

12.0mm ± 0.1mm

|

|

3

|

Wall thickness

|

ANMASPC |

1.00mm ± 0.10mm

|

|

4

|

Inner diameter clearance

|

Blowing steel ball

|

A 8.5mm steel ball can be blown freely through the duct.

|

|

5

|

Ovality

|

ANMASPC |

≤ 5%

|

|

6

|

Pressurization

|

5 minutes @ 16bar each duct

|

No damage and leakage

|

|

7

|

Kink

|

IEC 60794-1-2 Method E10

|

≤ 120mm

|

|

8

|

Tensile strength

|

Rate of extension:

100mm/min |

≥ 620N

|

|

9

|

Crush

|

Sample length: 250mm

Load: 380N Duration of Max. load: 1 min Recovery time: 1 hour |

No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test.

|

|

10

|

Impact

|

IEC 60794-1-2 Method E4

1.0J Impact, recovery time 1 hour |

No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test.

|

|

11

|

Heat reversion

|

110℃ ~ 23℃, 1 hour

|

≤ 3%

|

|

12

|

Min. bend radius

|

144mm

|

No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test.

|

|

13

|

Co-efficient of Friction

|

750mm Diameter, 450°loop, 5kg mass

|

≤ 0.1

|

|

14

|

Color and printing

|

Visual inspection

|

As per customer specification

|

|

Test

|

Characteristic

|

Test Method

|

Acceptance Criteria

|

|

Physical and Mechanical Properties – tube bundles

|

|||

|

1

|

Visual appearance

|

Visual inspection,

Outer sheath: Black |

Ribbed inside & smooth outside surface, free from blisters, shrink hole, flaking, scratches & roughness.

|

|

2

|

Outer diameter

|

ANMASPC |

35.8mm (± 1.1mm)

|

|

3

|

Sheath Wall thickness

|

ANMASPC |

3.40mm ± 0.20mm

|

|

4

|

Pressurization

|

5 minutes @16bar each duct

|

No damage and leakage

|

|

5

|

Tensile strength

|

Rate of extension:

100mm/min |

≥ 4600N

|

|

6

|

Crush

|

Sample length: 250mm

Load: 2000N Duration of Max. load: 1 min Recovery time: 1 hour |

No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test.

|

|

7

|

Impact

|

IEC 60794-1-2 Method E4

10.0J Impact, recovery time 1 hour |

No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test.

|

|

8

|

Min. bend radius

|

720mm

|

No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test.

|

|

9

|

Color and printing

|

Visual inspection

|

As per customer specification

|

Completed packages of the HDPE micro duct on drum can be stored outdoor max. 6 months upon the date of production. Storage temperature: -40°C ~ +70°C Installation temperature: -30°C ~ +50°C Operating temperature: -40°C ~ +70°C

Write your message here and send it to us