The Air-Blown Microfiber Optic Cable system is specifically engineered for underground duct networks, providing a comprehensive solution for a variety of applications such as backbone networks and FTTx. This product range offers designs suitable for high fiber density or small cable diameters, all tailored to minimize both cable and duct diameters, thereby ensuring a cost-effective installation process.

Microfiber Optic Cables are propelled through a network of microducts using compressed air, allowing for the flexibility to deploy fiber only when required, effectively reducing initial investment costs. This approach also guarantees the use of the latest fiber optic technology, making it scalable to meet evolving market demands. the system can be utilized to bypass existing networks and conduits, mitigating network disruptions and costly excavation expenses during the installation phase. The lightweight and flexible characteristics of the Microfiber Optic Cable, combined with its specially designed low-friction jacket, enable longer jetting lengths, further reducing both time and cost.

The Air Blown Application

Technology & Features of Air Blowing Cable

Air Blowing Fiber Optical Cable Machine

- comparing the laying methods of Air Blowing cable with other Fiber Optic cables, it is evident that the tension of Air Blowing cable during the laying process is notably uniform and significantly reduced in comparison.

- the laying process for Air Blowing cable is simplified and expedited, enabling it to cover long distances in a single operation, thereby reducing the number of joints and minimizing attenuation. The utilization of Air Blowing cable also results in a substantial reduction in the requirement for manholes and hand holes along the pipeline, as well as a decrease in the manpower needed for the laying operations.

- this innovative technology ensures future flexibility by facilitating the convenient replacement of optical fiber types, allowing for continued technological leadership and alignment with market needs.

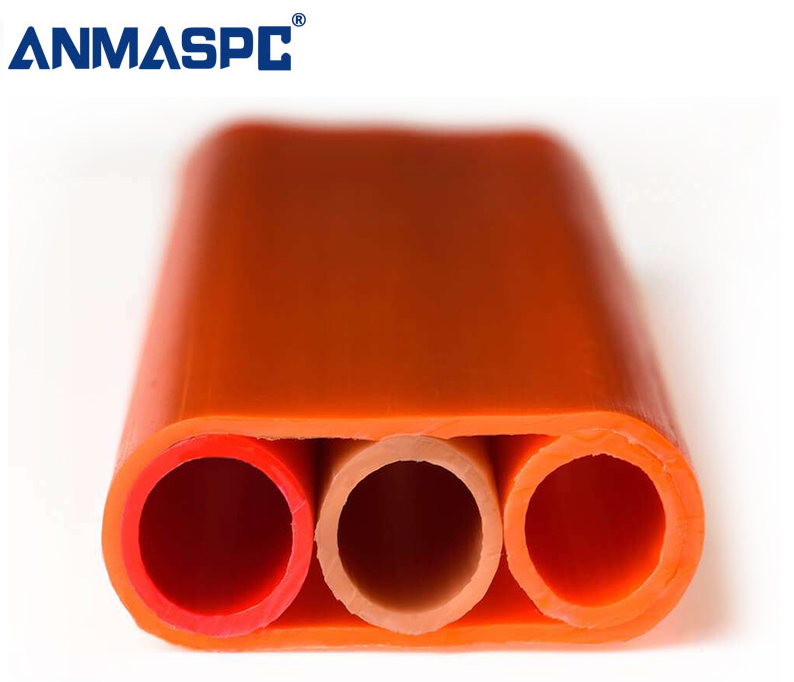

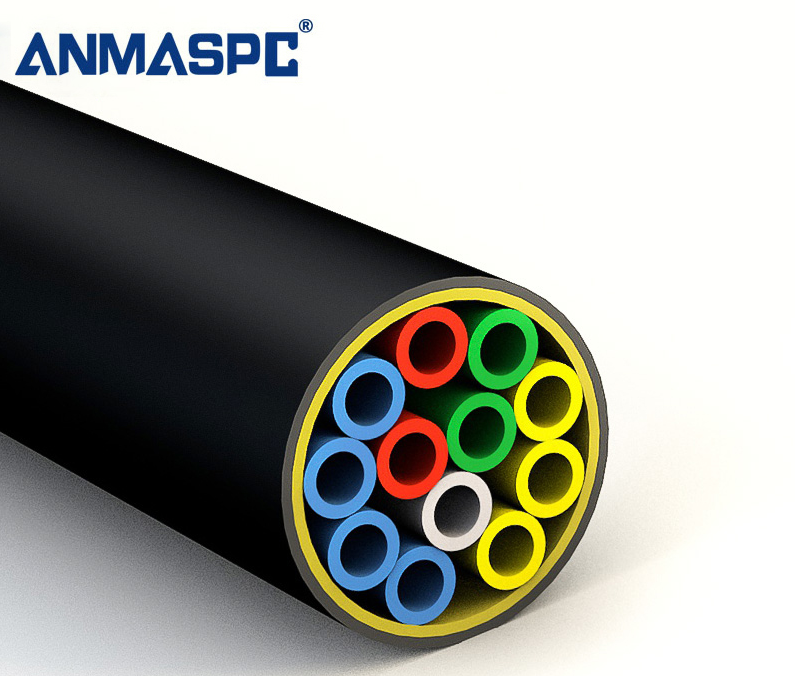

There are 3 variations of HDPE Microduct Fiber Optic Cable intended for blowing use, including microducts enclosed within a protective HDPE sheath.

2. HDPE multiple MicroDucts

3.High performance air blown cable

The high-performing single-core micro ducts feature permeable microtubes and are enclosed in polyethylene, enabling a higher density of tube apertures in a confined area. The separate bundling of microtubes makes inspection and expansion more convenient. Furthermore, the external enclosure enhances the mechanical resilience of the microtubes.

Package:

Contact Lily

Wechat/Whatsapp:+8618658796686

Email:lilu.chen@ouluaotomatic.com

Post time: Mar-29-2024