In recent years, the use of HDPE microcatheters has grown in popularity due to its numerous advantages and applications in various industries.

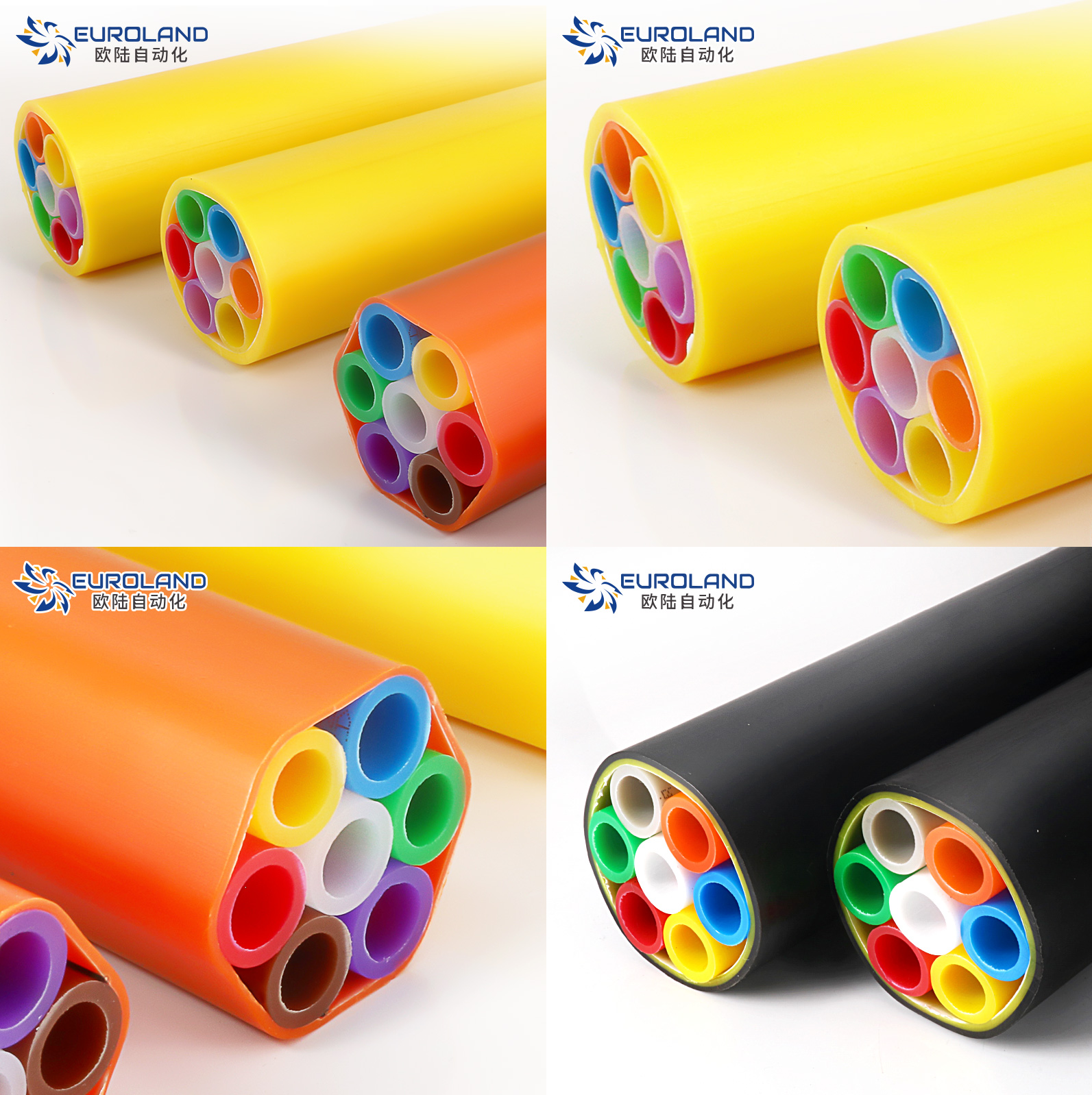

High-density polyethylene (HDPE) is a strong, flexible, and durable plastic ideal for use in microcatheters. These tubes are usually small in diameter, ranging from 5 mm to 20 mm, and are used to protect and route fiber optic cables, telecommunication wires and other types of small cables.

One of the main advantages of HDPE microtubes is their ability to protect cables from external elements such as moisture, dust and physical damage. These tubes act as a barrier, protecting the cables from any potential hazards that could cause them to malfunction or fail. This is especially important in industries such as telecommunications and data centers where reliable and secure cabling is critical.

HDPE microtubing is also easy to install and maintain. They are lightweight and easy to transport and install, reducing installation time and associated costs. These tubes also require minimal maintenance as they are not prone to corrosion or wear, which ensures long-term performance and reliability of the cables they protect.

Besides telecommunications and data centers, HDPE micropipes have many other applications, such as in the construction industry. They are used to protect cables and conduits, pipes and drains, and air conditioning ducts. These tubes make the installation and maintenance of these systems easier and reduce the risk of damage due to adverse weather conditions or construction work.

Another important application of HDPE microtubules is in the healthcare industry. They are used to route medical gases and other types of specialty cables within hospitals and clinics. These tubes help ensure patient safety as they prevent harmful substances such as bacteria and viruses from seeping into the medical gas supply.

In addition to their functional advantages, HDPE microtubules are also environmentally friendly. They are recyclable, reducing the amount of plastic waste that ends up in landfill.

Despite its many assets, working with HDPE microtubules can pose certain challenges. One of the main disadvantages is that they can create kinks or bends in the internal wiring. This can cause signal distortion or loss, which can destroy the performance of the cable. Another challenge is the increased risk of cable crushing, which can occur during installation or construction, resulting in costly repair or replacement.

In conclusion, due to the advantages and applications of HDPE microtubules in various fields, their use is becoming more and more popular. These tubes provide reliable cable protection, ease of installation and maintenance, and environmental sustainability. However, users must be aware of the potential challenges they present, such as signal distortion or the risk of cable pinching. Despite these challenges, HDPE microtubules remain valuable assets in modern industry.

Post time: Jun-12-2023