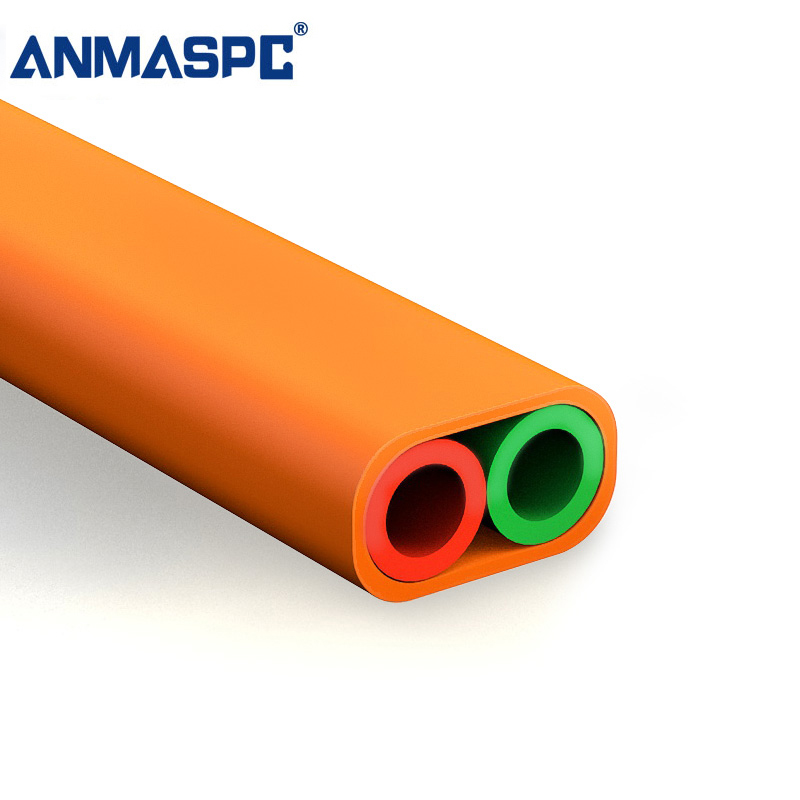

HDPE 2 way

HDPE 2ways 14/10 MM

|

Physical and Mechanical Properties – Inner Micro duct 14/10mm

|

|||

| 1 | Visual appearance | Visual inspection | Ribbed inside & smooth outside surface, free from blisters, shrink hole, flaking, scratches & roughness. |

| 2 | Outer diameter | FCST | 14.0mm ± 0.1mm |

| 3 | Wall thickness | FCST | 2.00mm ± 0.10mm |

| 4 | Inner diameter clearance | Blowing steel ball | A 8.5mm steel ball can be blown freely through the duct. |

| 5 | Ovality | FCST | ≤ 5% |

| 6 | Pressurization | 5 minutes @25bar each duct | No damage and leakage |

| 7 | Kink | IEC 60794-1-2 Method E10 | ≤ 140mm |

| 8 | Tensile strength | Rate of extension: 100mm/min |

≥ 1350N |

| 9 | Crush | Sample length: 250mm Load: 1400N Duration of Max. load: 1 min Recovery time: 1 hour |

No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test. |

| 10 | Impact | IEC 60794-1-2 Method E4 1.5J Impact, recovery time 1 hour |

No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test. |

| 11 | Heat reversion | 110℃ ~ 23℃, 1 hour | ≤ 3% |

| 12 | Min. bend radius | 168mm | No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test. |

| 13 | Co-efficient of Friction | 750mm Diameter, 450°loop, 5kg mass | ≤ 0.1 |

| 14 | Color and printing | Visual inspection | As per customer specification |

| 1 | Inner micro duct: | 14/10mm |

| 2 | Outer Diameter: | 30.4mm * 16.4mm (±0.5mm) |

| 3 | Thickness of sheathing: | 1.2mm |

| Remarks: Ripcord are optional. | ||

Raw materials:

HDPE of a high-molecular type with the following parameters is used for production of the Tube Bundle: - Melt flow index: 0.1 ~ 0.4 g/10 minutes EN ISO 1133 (190 °C, 2.16 KG) - Density: Min. 0.940 g/cm3 ISO 1183 - Tensile strength at yield: Min. 20MPa ISO 527 - Elongation at the break: Min 350% ISO 527 - Environmental stress crack resist (F50) Min. 96 hours ISO 4599

Construction

| Pos. | Mechanical performance | Test conditions | Performance | Standard |

| 1 | Tensile strength at yield |

Rate of extension: 100mm/min |

≥1400N | IEC 60794-1-2 Method E1 |

| 2 | Crush | Sample length: 250mm Load: 1400N Duration of Max. load: 1 minutes Recovery time: 1 hour |

The outer and inner diameter shall show, under visual examination without damage and no reduction of diameter greater than 15%. | IEC 60794-1-2 Method E3 |

| 3 | Kink | ≤140mm | - | IEC 60794-1-2 Method E10 |

| 4 | Impact | Striking surface radius: 10mm Impact Energy: 1J Number of impact: 3 times Recovery time: 1 hour |

Under visual examination, there shall be no damage to the micro duct. | IEC 60794-1-2 Method E4 |

| 5 | Bend radius | Number of turns: 5 Mandrel diameter: 168mm Mumber of cycles: 3 |

The outer and inner diameter shall show, under visual examination without damage and no reduction of diameter greater than 15%. | IEC 60794-1-2 Method E11 |

| 6 | Friction | / | ≤0.1 | FCST |

| Pos. | Item | Specification | |

| 1 | Appearance | Smooth outer wall (UV-stabilized) without visible impurities; well-proportioned color, no bubbles or cracks; with defined markings on outer wall. |

|

| 2 | Tensile strength | Use Pull socks to tension a sample in accordance with table below: Sample length: 1m Tensile speed: 20mm/min Load: 2200N Duration of the tension: 5 min. |

No visual damage or residual deformation greater than 15% of the duct assembly outer diameter. |

| 3 | Crush Resistance | A 250mm sample after 1 minute load time and 1 hour recovery time. Load (plate) shall be 2000N. The imprint of the plate on the sheath is not considered as mechanical damage. |

No visual damage or residual deformation greater than 15% of the duct assembly outer diameter. |

| 4 | Impact | Striking surface radius shall be 10mm and impact energy 3J. Recovery time shall be one out. The imprint of the striking surface on the microduct is not considered as mechanical damage. |

No visual damage or residual deformation greater than 15% of the duct assembly outer diameter. |

| 5 | Bend | Diameter of mandrel shall be 40X OD of sample, 4 turns, 3 cycles. | No visual damage or residual deformation greater than 15% of the duct assembly outer diameter. |

Single-Hole Microtube

The most basic component of the micro-pipe system is high density polyethylene(HDPE plastic pipe,which can be simply described as “small-sized silicon core pipe”)with a nominal outer diameter of not more than 16mm,The inner wall of the pipe has a permanent solid silicon core lubricating layer, and some specifications of micro-longitudinal guide rib groove structure on the inner wall of the micro-pipe can further reduce the friction between the inner wall of the pipe and the cable, which is beneficial to the laying of optical cables by air blowing. A variey of microtubes can be selected by customers. The most commonly used specifications include Ø10/8mm,Ø12/9mm,Ø14/10mm.

Cluster Tube

In the bundle pipe, porous microtubes are arranged and combined according to a certain way,and the outer layer is coated with polyethylene sheathe to form the bundle pipe, so that more tube holes can be accommodated in a limited space. The bundled microtubes are independent of each other,which is convenient for the identification and connection of microtubes. The outer layer sheath provides better mechanical lightness for the microtubes.

Product Characteristics

1. The inner wall of microtube never falls off, and friction coefficient is very small,so it is very easy for optical cable to be extracted in the pipeline.

2. The radius of curvature of microtube is small ( ten times of its outer diameter). When laying, the bends and drops are encountered, which can be determined according to the topography of Hanjing, without any treatment, let alone setting up excessive wells.

3. The length of each microtube (disc) can be made into any length. Generally, considering transportation safety and construction blow-out technology,the standard length of each microtube(disc) is set at 200M.

4. The background color and color bar of microtubeles can be determined according to the actual situation of the project. To enhance the antixidant capacity of microtubules, we recommend using microtubules with air guide grooves on the inner wall of white ground. This kind of micro-plastic pipe can prolong its service life, and can also effectively divide trenches and lay multiple pipe, such as white, blue,yellow,red and orange.

specification

| No. | Project | 4 ways Bundle Tube 12/9mm | |

| 1 | Structural Diagram |  |

|

| 2 | Appearance | Single-hole mictubes forming bundle tubes should have uniform wall thickness at any interface,w/o pores or defects and the outer and inner surface should be free of crackd, holes,water stains,repairs and any other defects.There shall be no obvious crack on any interface of the sheath layer of the bundle pipe over the whole delivery length,and there shall be no adhesion between the microtube inside the hole and sheath layer of the bundle pipe. | |

| 3 | Physical Dimension | Outside Diameter Nominal Value(mm):34.0 | Wall thickness(mm):2.5±0.2 |

| 4 | Tensile Yield Strength | ≥21Mpa | |

| 5 | Breaking Elongation | ≥350% | |

| 6 | Compressive Strength | 2000N | |

| 7 | Longitudinal Retraction Rate | ≤3% | |

| 8 | Microtubule Crushing Force | microtubes under 450N crushing load,no cracking no permanent damage | |

| 9 | Impact Test | Under the condition of negative 20℃ and height of1.5m impact,10 samples with 15.3KG heavy hammer,and at least 9 samples shall not crack. | |

| 10 | Coefficient of Internal Friction | ≤0.1 | |

| 11 | Microtubule Pressure Test | 1.6Mpa | |

| 12 | Environmental Stress Cracking Resistance | 96h,Failure No.≤20% | |

| 13 | Operating Temperature Range | -40℃-70℃ | |

Material: Hybrid low smoke zero halogen microduct with unre recycled material

Production Standard:

the inner wall must be fluted, slippery and have a low coefficient of friction without the need for additional wet lubricants.

The microduct must not have any insulated copper wire inside and no ripcords.

Identification Color: according to the customer`s standard code,such as blue,orange, green, brown, gray, white, red and black

Usage:suitable for fibre management

QC System: quality check by specially machine

Package: by disc

After Service: Technology skill by video

Min QTY:1000 Meters

Payment Terms: By T/T

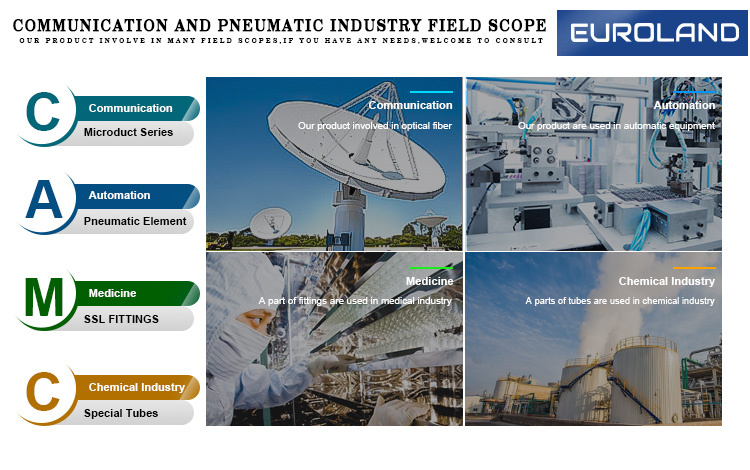

Company Profile