HDPE compression fittings have gained significant popularity due to their durability, versatility, and ease of installation in plumbing and piping systems. These mechanical fittings effectively connect HDPE pipes to fixtures or valves, ensuring a secure and leak-free connection. In this article, we will delve into the intricacies of HDPE compression fittings, exploring their components, applications, and advantages.

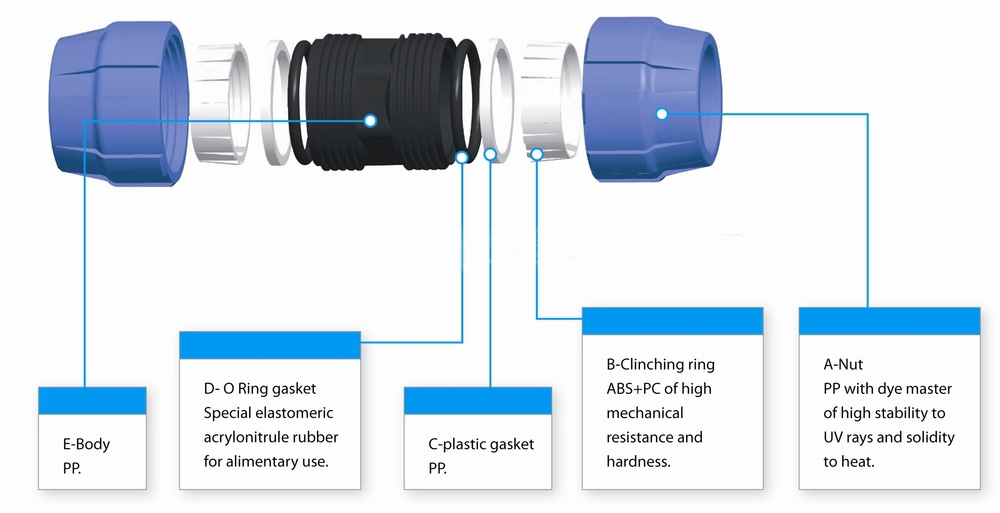

Compression fittings, as the name suggests, involve the compression of specific parts to create a tight seal between pipes. HDPE compression fittings primarily consist of three essential components: the compression nut, the compression ring, and the compression seat. Let’s take a closer look at each of these components:

1. Compression Nut:

The compression nut, made from robust materials like stainless steel or brass, is responsible for applying pressure to the compression ring. By tightening the nut, it compresses the ring onto the HDPE pipe, creating a watertight connection. The compression nut typically features hexagonal or knurled designs to facilitate easy gripping and tightening.

2. Compression Ring:

The compression ring, also known as the ferrule, is typically manufactured from high-quality materials like polyethylene or polypropylene. Its primary purpose is to evenly distribute the compression force onto the HDPE pipe, minimizing the risk of leakage. Additionally, the design of the compression ring plays a crucial role in ensuring that the connection remains intact under high pressure and temperature conditions.

3. Compression Seat:

The compression seat is the portion of the fitting that the pipes are inserted into. This seat provides stability and a secure fit for the pipes, allowing the compression nut and ring to create a tight seal. It is essential to ensure that the compression seat is compatible with the HDPE pipe size, as an inadequate fit could compromise the integrity of the connection.

These three components work in harmony to create a reliable and durable connection between HDPE pipes. The advantages of using HDPE compression fittings are manifold:

1. Versatility:

HDPE compression fittings are compatible with various sizes and types of HDPE pipes, offering flexibility in plumbing and piping systems. Whether it is a residential, commercial, or industrial application, these fittings can cater to diverse requirements.

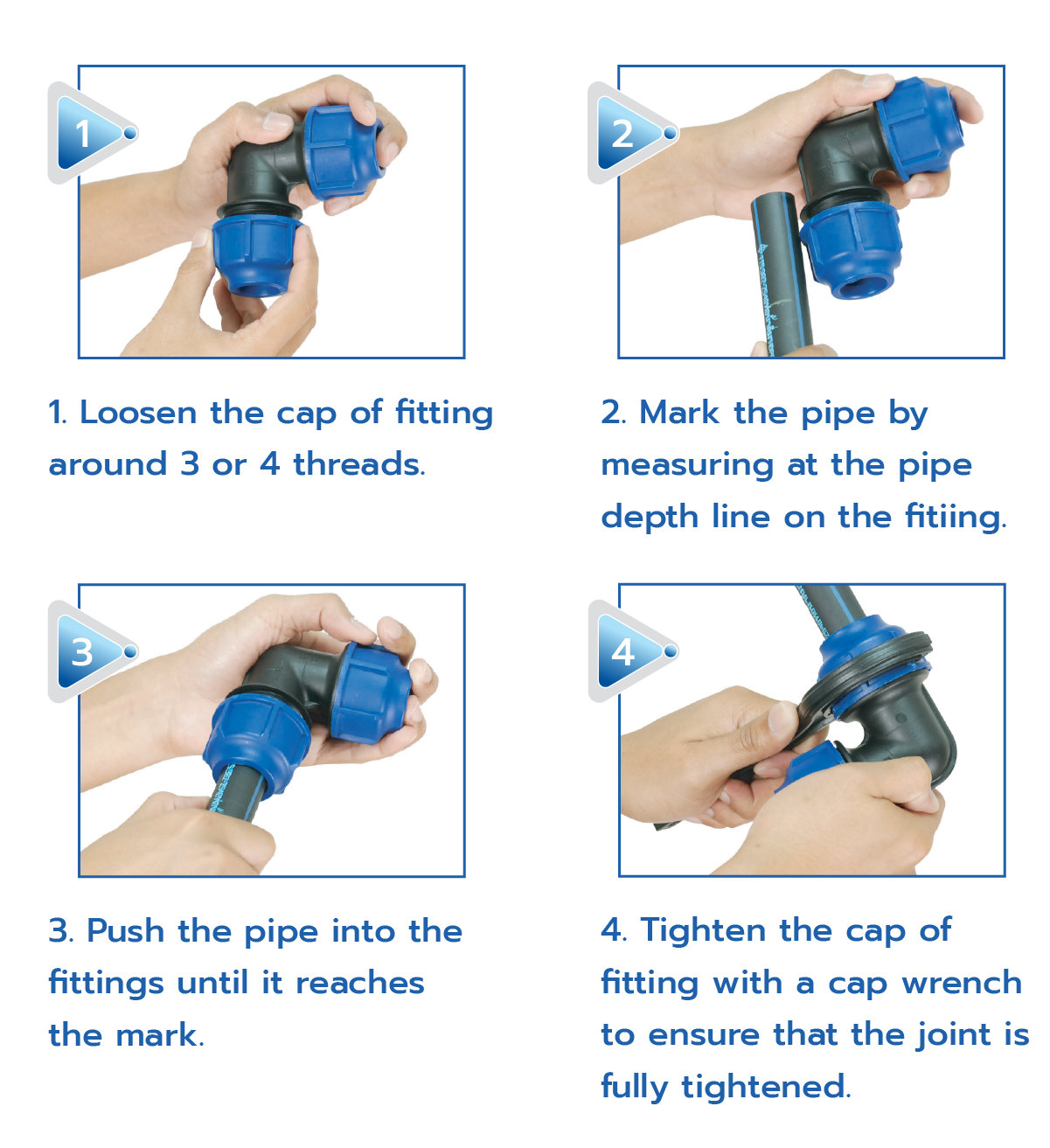

2. Easy Installation:

One of the significant advantages of HDPE compression fittings is their user-friendly installation process. With minimal tools and expertise required, these fittings can be quickly assembled, saving time and labor costs.

3. Leak-Free Solution:

HDPE compression fittings are designed to create a secure and leak-free connection. The compression nut exerts pressure on the compression ring, effectively sealing the joint. This prevents water leakages, ensuring the integrity and efficiency of the plumbing or piping system.

4. Chemical and Corrosion Resistance:

HDPE compression fittings offer excellent resistance to various chemicals, making them ideal for applications in industries such as agriculture, mining, and wastewater treatment. Additionally, their robust construction provides resistance against corrosion, extending the lifespan of the fittings.

5. Durable and Long-lasting:

HDPE compression fittings are built to withstand immense pressure, temperature fluctuations, and environmental factors, ensuring long-term durability. By choosing these fittings, users can reduce maintenance costs and enjoy a reliable plumbing system for years to come.

6. Cost-Effective Solution:

Thanks to their versatility, durability, and easy installation, HDPE compression fittings offer a cost-effective solution for various plumbing and piping projects. Their longevity and minimal maintenance requirements contribute to significant cost savings in the long run.

HDPE compression fittings find widespread application in plumbing systems, irrigation networks, water supply systems, and industrial piping. From residential projects to large-scale infrastructure development, these fittings have become a preferred choice due to their numerous advantages.

HDPE compression fittings provide a reliable, leak-free, and cost-effective solution for connecting HDPE pipes. With their versatile applications and ease of installation, these fittings have revolutionized the plumbing and piping industry. From ensuring efficient water supply systems to facilitating effective waste management, HDPE compression fittings play a vital role in enhancing the overall performance and functionality of various systems.

Post time: Aug-15-2023