The Micro Duct connectors were developed to connect microducts with each other.Our system enables an easy, fast connection and disconnection of the microduct. The connectors’ robust construction resistance to high pressure forces,allowing them to be used in direct buried (DB) applications. The transparent body enables easy visual inspection of the cable with in the connector.

Micro Duct Connector Material Structure Diagram

To match microduct complete connections of different sizes, ANMASPC provides customers with full-size Micro Duct connector. These include Micro Duct Straight Connector, Micro Duct Reducer, Micro Duct End Stop Connector, and Gas-Water Block Micro Duct Reducer, Gas-Water Block Micro Duct Connector, Direct Buried Straight Connector, Divisible Duct Sealing, Divisible Mini Micro Duct Seal, HDPE Silicon Core Pipe Connector, Simplex Duct Plug, HDPE Silicon Core Pipe Connector, Expanding Duct Plug, etc.

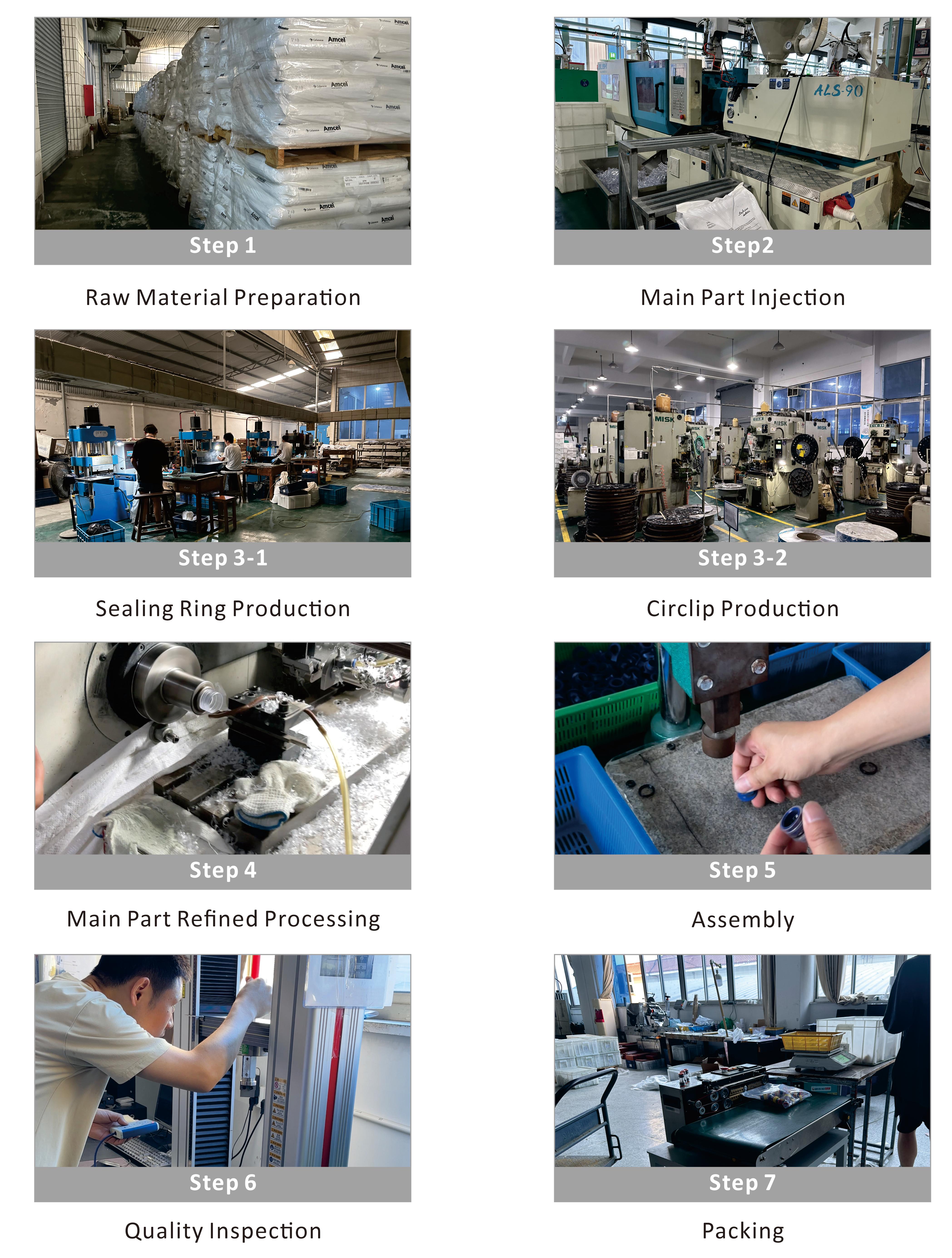

Excellent quality products, there is a complete production process to support, and then take you to understand how the Micro Duct connectors is made into a perfect product.

Production Procedure

Step 1: raw material preparation.The raw materials are imported from the Middle East to ensure that the stability of the materials is high.

Step 2: Connector body injection production.The plastic part is quickly produced by injection molding machine.

Step 3-1: Connector fittings – sealing ring production.By weighing the weight of the material, ensure the quality of the products produced.

Step 3-2:Connector fittings – circlip production.Stainless steel bands produce CIRCLIP accessories that match different sizes through stamping machines.

Step 4:Connector body part finishing.In order to better assemble, the main part needs to be processed by machine.

Step 5: Product assembly.All assembled accessories are assembled into finished products.

Step 6: Product quality inspection.According to the probability of five thousandths, the product was spot -checked, and tension testing, pressure testing and other testing were performed.

Step 7: Product packaging.The quality of the quality pass is packed through the machine.

Production Procedure of the Micro Duct Connector

ANMASPC – Better FTTx, Better Life.

We have been designing, manufacturing and supplying microduct connectors for fiber optic networks since 2013. As a supplier of micro-tube connectors, we will continue to develop and update our products to contribute more to the construction of global optical fiber networks.

Post time: Aug-03-2023